Traditions

Fujiya’s Tenugui have many traditions. We care about the process of dyeing very much.

The process of making Tenugui

Preparations

Fujiya’s traditions start before dyeing. For the ink to dye well, the cotton is washed in warm water many times to remove small dust particles. It takes time and labor to wash many times but this process is important to dye magnificently.

After washing the cotton, we start dyeing

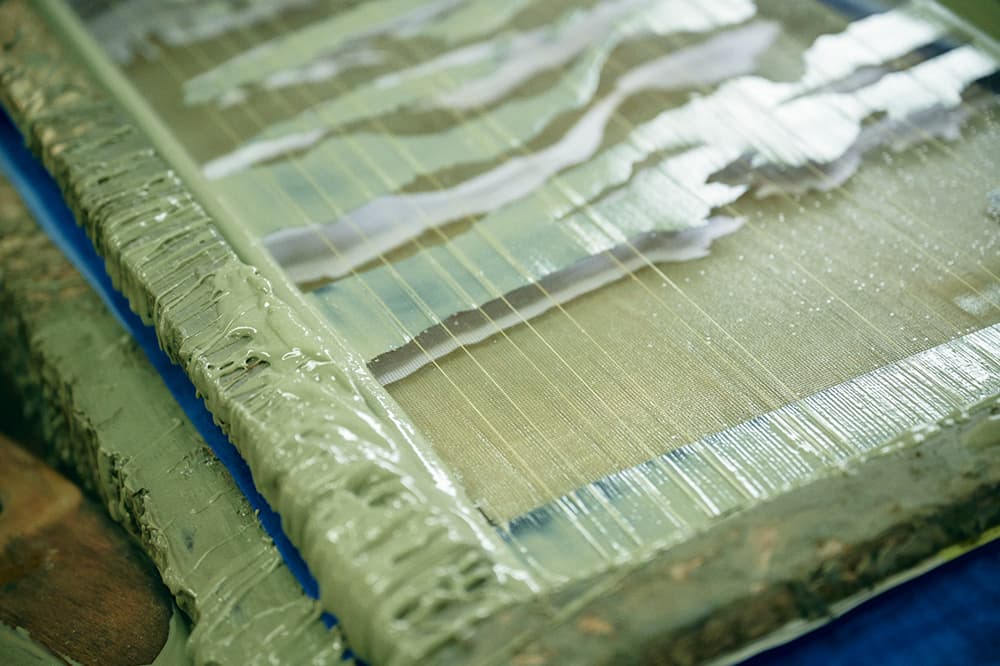

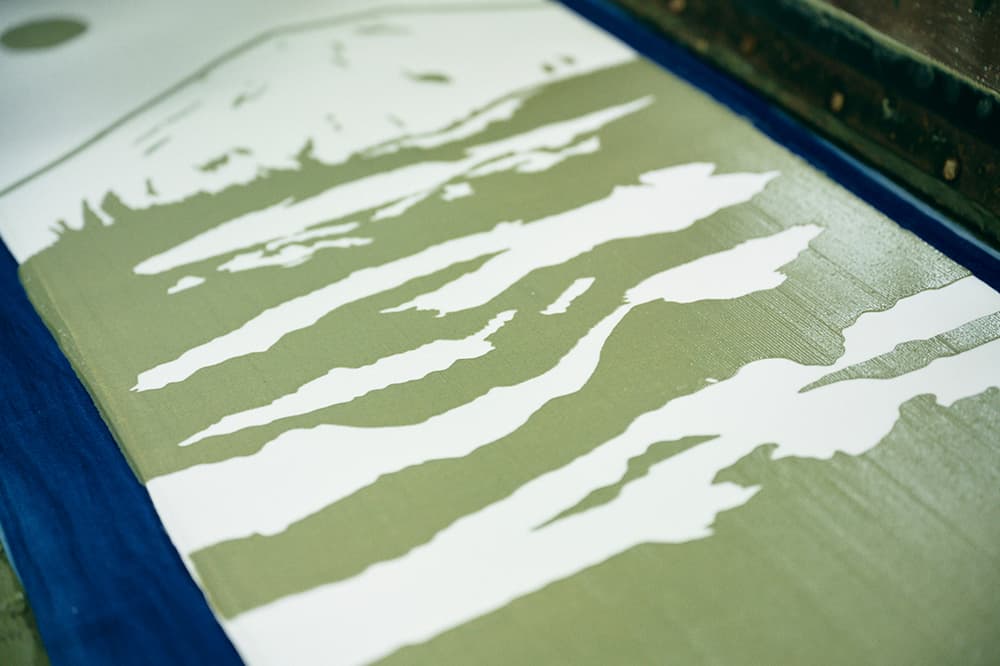

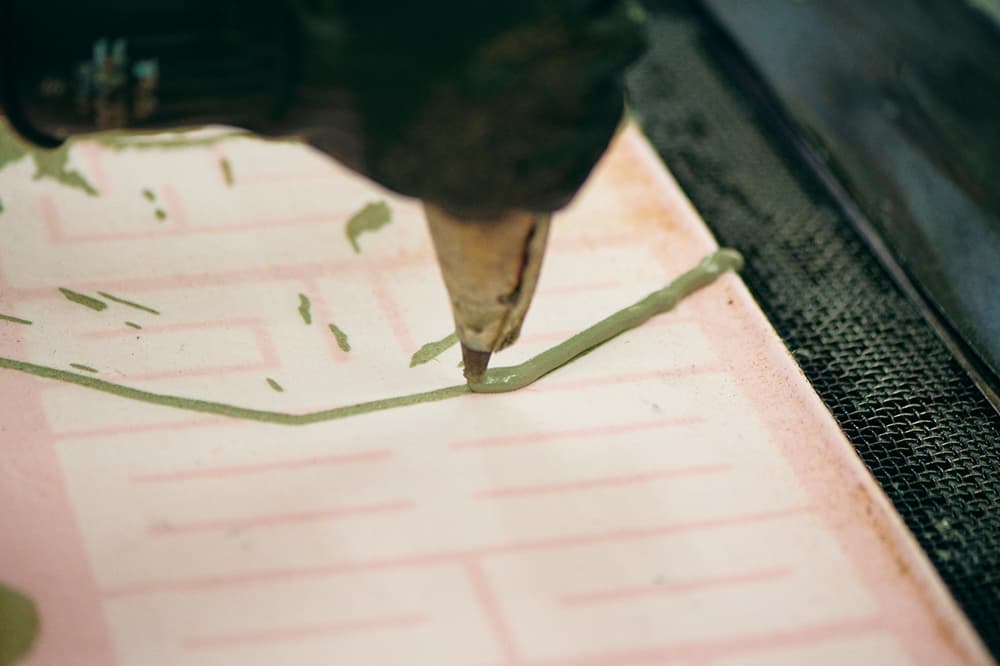

Applying glue

Apply the glue by hand to separate the designs where ink should not be dyed. Skilled artisans apply the glue very carefully and the process is like putting love into the Tenugui.

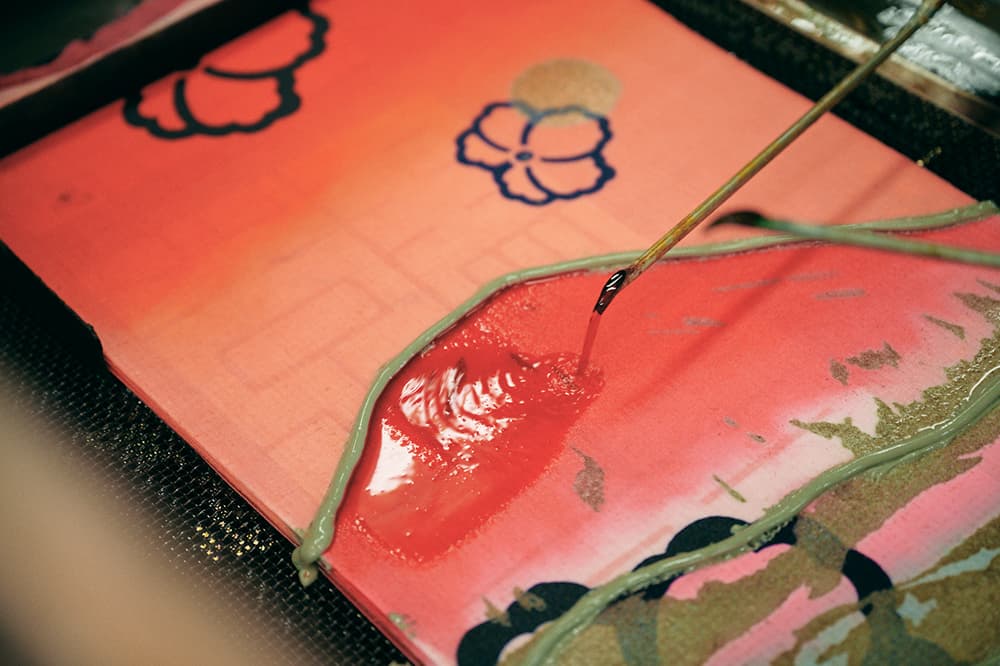

Dye ink on glue-designed cotton

Hand dyeing

Our dyeing method is ”Chuzen Zome". Unlike for print, it dyes through the material with no distinction between front and back.

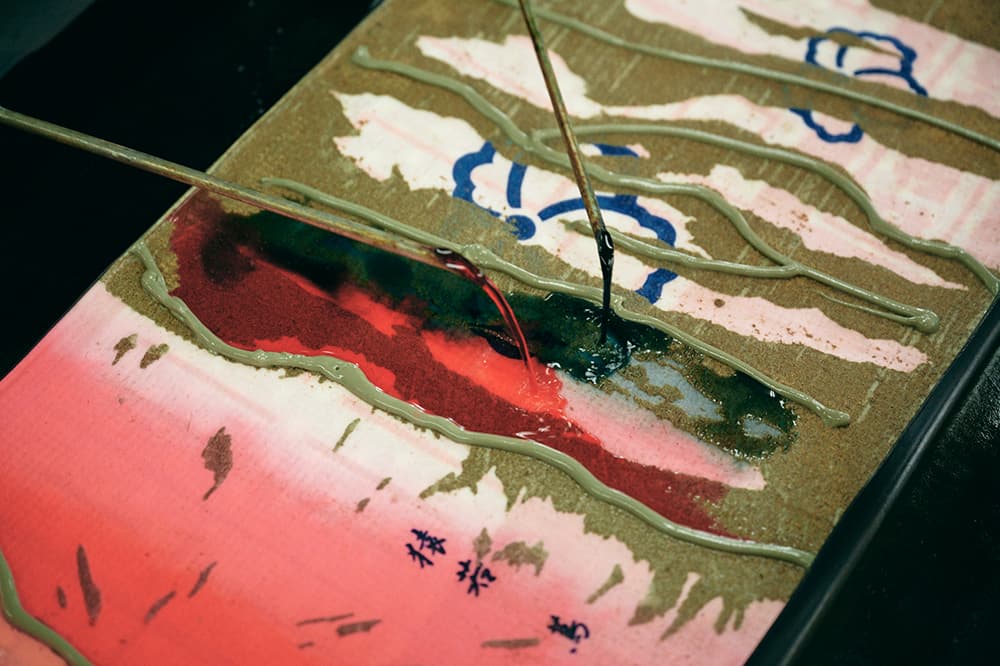

After gluing the design where color is not wanted, dye is poured onto the cotton. Using a large-sized special kettle, the ink is poured into the designs. While pouring the ink, the ink gets absorbed right away. Rhythmically this process of pouring and absorbing continues.

Once the dyeing is complete, the glue is washed away. If the designhas many colors, this process continues many times. It takes labor to dye magnificently.

Our skilled artisans prepare the cotton and apply the glue for dying. Our mission is to continue to make authentic Tenugui.

With divine sun for the final step

Dry

Wash the dyed cloth and put it into the hydro extractor

Dry it on the rack under the sun.

Remove the wrinkles after they are dried.Cut the long cloth into the Tenugui length.

Display them at the store.